Enserve Environmental Services introduced its emission monitoring services to the petrochemical industry in 2001. Since then, we’ve evolved from traditional “sniff-and-tag” methods to advanced Smart LDAR (Leak Detection and Repair) solutions.

In chemical, petrochemical plants and refineries volatile organic vapours and gaseous products losses mainly originate from valve glands. Deterioration of packing material over a period of time requires regular monitoring, gland adjustment and eventual replacing of the gland packing before the gland has completely “bottomed out”.

In a nutshell depots and plants with storage facilities are obliged by the National Environmental Act to survey all storage tanks and pressure vessels exceeding 14kpa for any medium, shape and size of tank/pressure vessel. Constantly striving to help depots and storage facilities reduce their losses to atmosphere.

A procedure adopted by Enserve Environmental obtaining quality boundary emission data over a 12 month period at 30 day intervals, to accumulate chemical pollutants in the environment. In passive sampling, average chemical concentrations are calculated over a device’s deployment time, which avoids the need to visit a sampling site multiple times to collect multiple representative samples.

Welcome to Enserve Environmental Services

At Enserve, we specialize in precise and reliable Leak Detection and Repair (LDAR) solutions for industrial environments. With a proven track record across the petrochemical, power generation, and manufacturing sectors, we are committed to helping our clients reduce fugitive emissions, improve safety, and ensure environmental compliance.

Our dedicated team uses state-of-the-art equipment and certified methodologies to identify, quantify, and mitigate leaks—ensuring your plant operates efficiently and within regulatory standards. Whether you’re preparing for a shutdown, seeking routine monitoring, or responding to an emergency, we tailor our LDAR services to meet your needs.

Thank you for visiting our site. We look forward to partnering with you in building a cleaner, safer, and more efficient future.

Our Mission

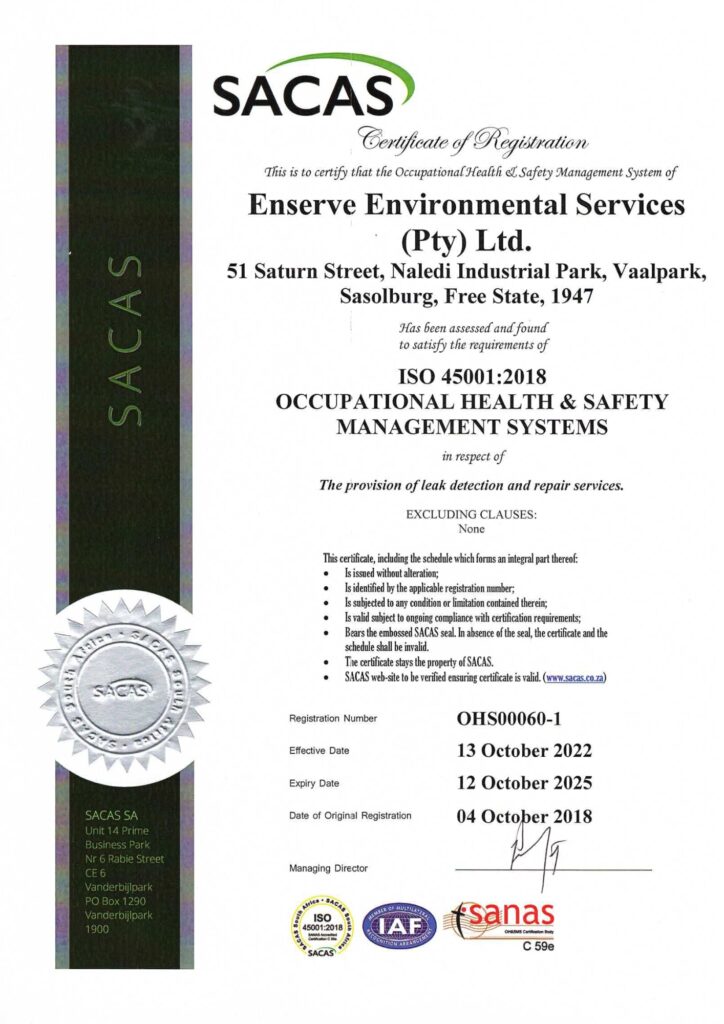

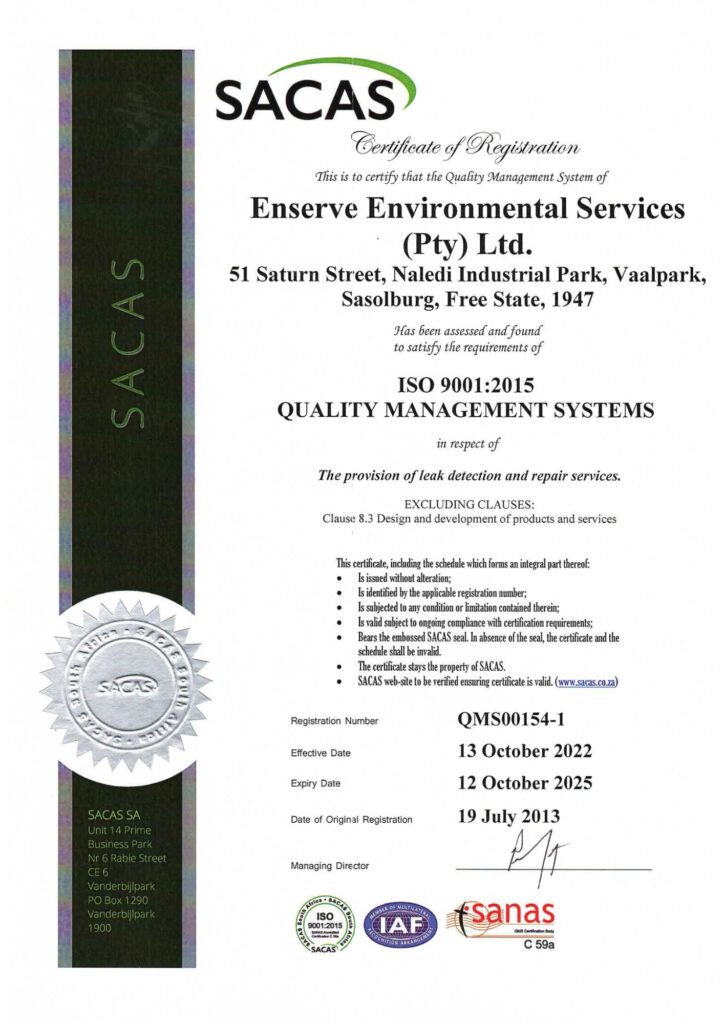

Certification

ISO 9001-2015 (Exp 12-Oct-25)

ISO 45001-2018 (Exp 12-Oct-25)